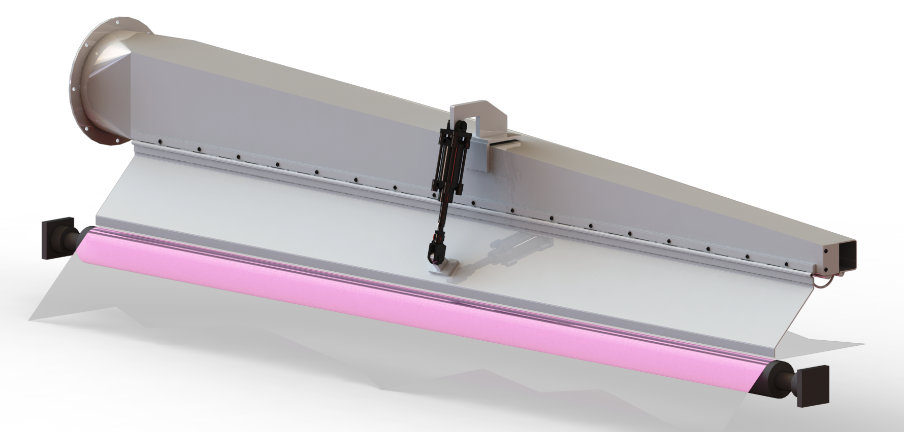

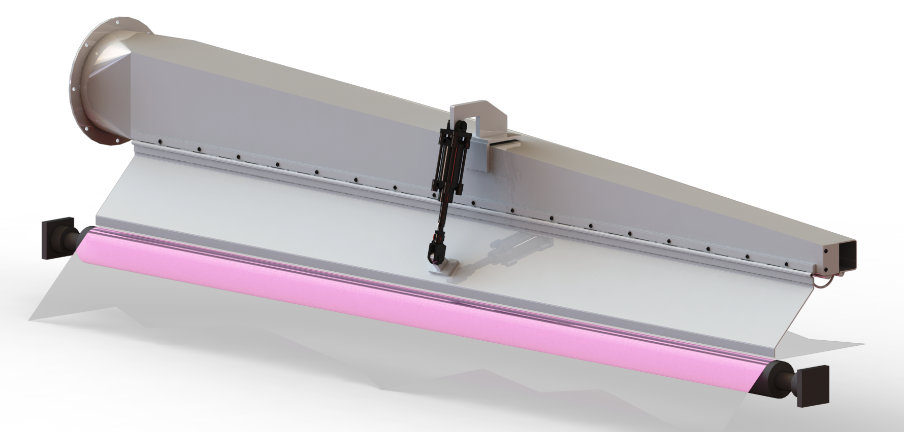

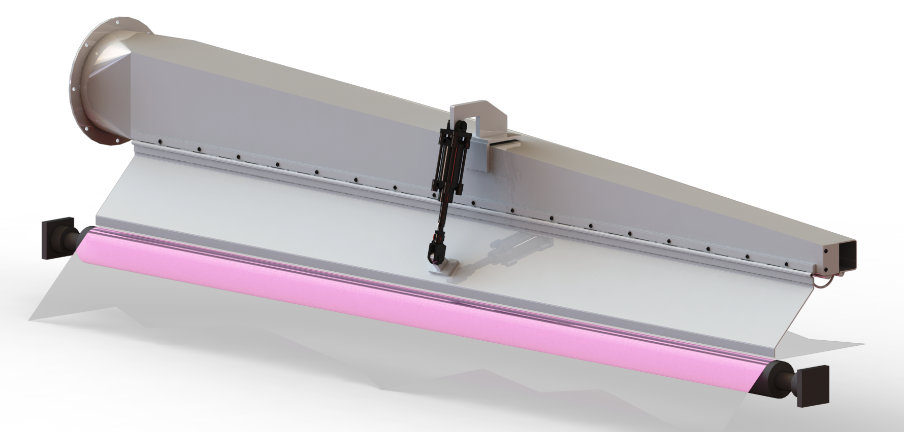

Close Capture dust hoods with pneumatic cylinder actuated stripping baffles demonstrate superior performance in papermaking and converting applications. In area where close capture hoods are not feasible (an unsupported web or spatial constraints) we utilize general Area exhaust hoods. This combination of close capture and area hoods are used successfully on weak sheets such as facial and tissue lines. They provide optimum dust collection performance that result in improved process reliability.

Features and Benefits

- Used as Close Capture or Area hoods.

- No internal baffles: no internal components or spacers to clog with paper shreds.

- Hoods achieve a uniform distribution of airflow along the entire slot length which is a crucial element in avoiding sheet breaks. Each hood is bench tested to verify uniform airflow.

- Designed to avoid capturing larger breakout sheet material (no need for inline paper traps)

- Airflow diverters are used to avoid airflow induced sheet breaks due to sudden machine speed changes.

- Achieve targeted breathing zone dust levels.

- Instrumental in reducing cleanup frequency and reducing fire hazards.

- Available in carbon steel, aluminum, and 304 stainless steel.

- Hoods can be designed to fit your specific application and spatial constraints. This allows for operation and maintenance functions.

STEIMEL METAL FAB LLC.

5009 Cincinnati Brookville Rd

Hamilton OH 45013

513-616-8647

Copyright ©2019 Steimel Metal Fab, LLC. All Rights Reserved.